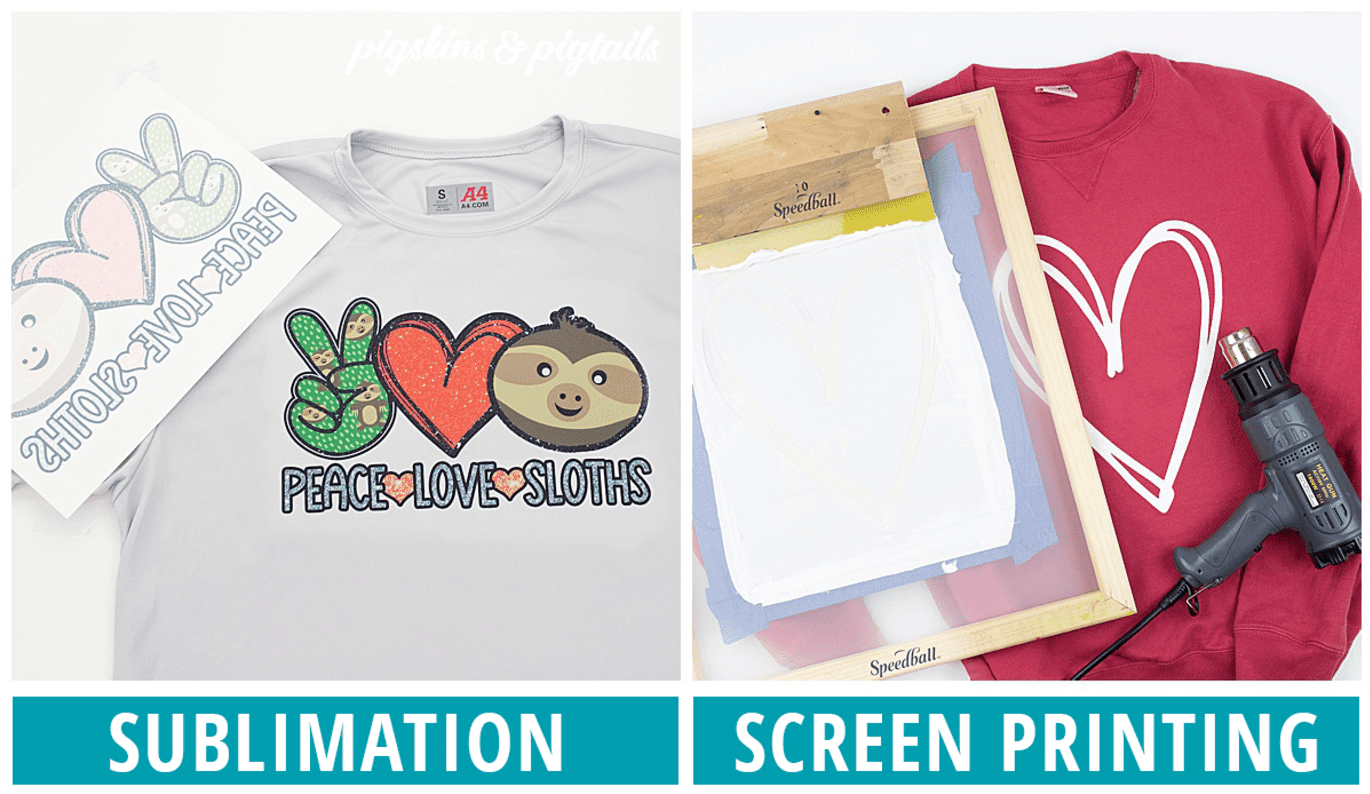

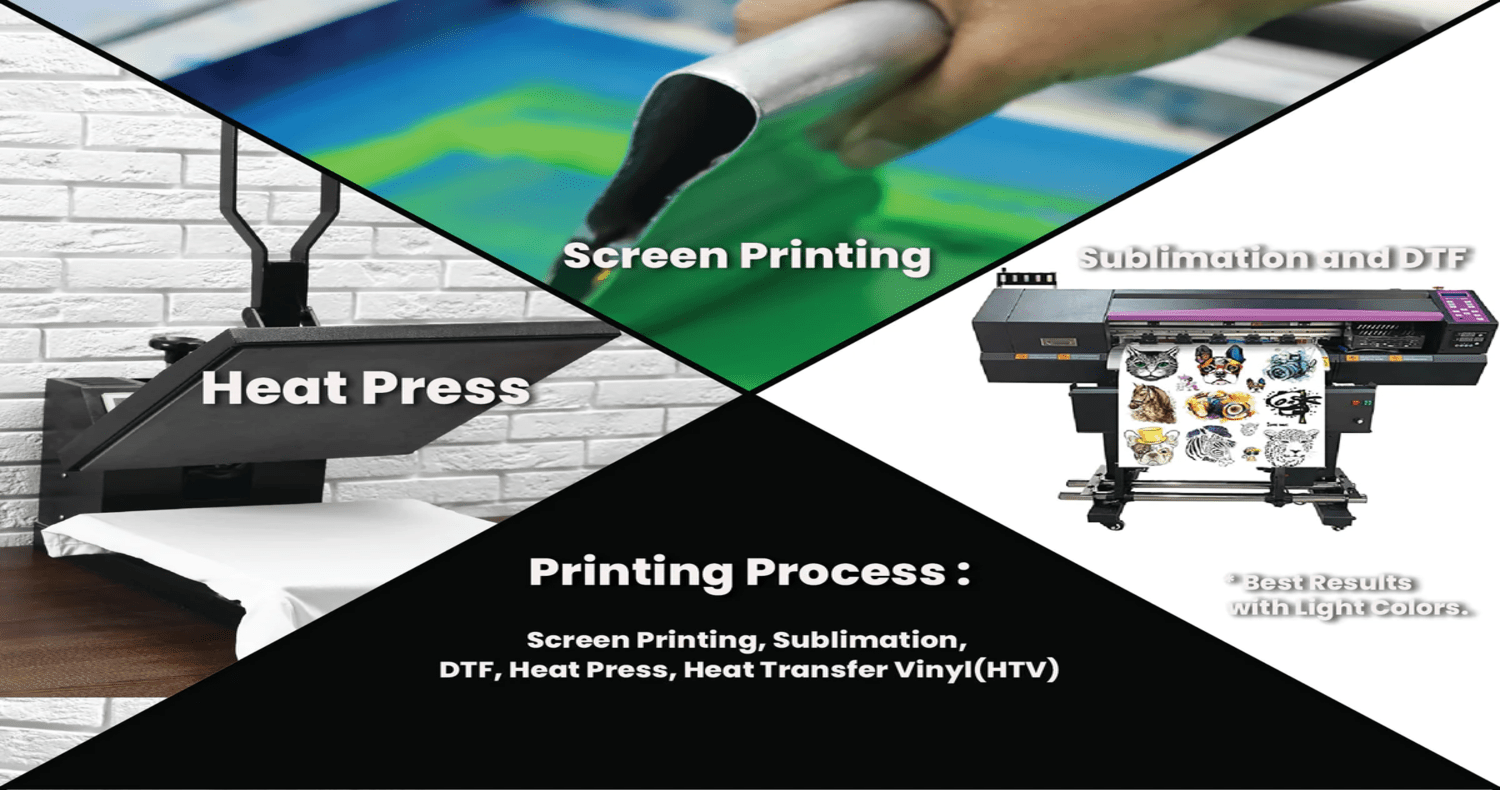

Navigating the decision between sublimation vs screen printing can be perplexing. Sublimation involves ink infusion in the materials while giving a long-lasting printed pattern. On the other hand, Screen printing is the technique used with stencils to craft bold designs. This guide delves into these methods, aiding businesses in navigating the intricacies of promotional material creation.

The primary difference between sublimation and screen printing is the technique used. Sublimation asks for transferring ink to the fibers, and screen printing uses stencils to transfer ink. Furthermore, the choice of the best method should depend upon the demand of the business, environmental conditions, budget, and durability factors.

Read further to understand both techniques and conclude what suits your business well. From cost considerations to the type of products each suits, this guide provides valuable insights for your decision-making process.

See Also: T-Shirt Printing Machine For Small Business

Table of Contents

Sublimation Printing: A Detailed Exploration

Before learning the difference between sublimation and screen printing, let’s understand what a sublimation press is:

Sublimation Printing is a technique that involves heat-based printing. Ink transforms into a gaseous state and is immersed within the materials. Additionally, this infusion results in vibrant and thick colors, which have more durability. Such methods are appropriate for designing fabrics or papers.

Additionally, this infusion results in vibrant and thick colors, which have more durability. Such methods are appropriate for designing fabrics or papers.

Process involved:

Here is the detailed process involved in sublimation press printing:

- Create the design on a computer using graphic software, ensuring accurate dimensions and color combinations.

- Use sublimation inks on transfer paper to replicate the design with high precision.

- Carefully overlap the printed paper on the material and release heat.

- Apply high heat to transform the ink into a gaseous form.

- Allow gas molecules to penetrate the fabric and bond firmly at the molecular level.

- Let the material cool down, allowing the ink to dry for a crisp and permanent outlook.

- Complete the process with garment cutting and sewing for the final product.

Applications of sublimation printing:

Now, let’s explore where sublimation printing can be applied:

Apparel: Customized t-shirts, streetwear, and fashion items are highly required for graphical printing by sublimation method. Learn how to design unique t-shirts through apps.

Home Décor: Graphic designs on Cushion covers, mugs, photo frames, coasters, etc, are done through this method.

Signage and Promotional Materials: Flags, banners, and promotional products benefit from the detailed and lasting prints achieved through Sublimation.

Materials Suitable for Sublimation:

Here are the materials suitable for achieving good-quality printing on a sublimation press:

- Polyester fabric: Gives the best outcome after polymer coatings

- Ceramics: hold on to the ink imprints

- Metals: Sublimation-compatible metals with a polymer layer.

Material used for Sublimation:

Understand the fundamental materials needed for the printing process:

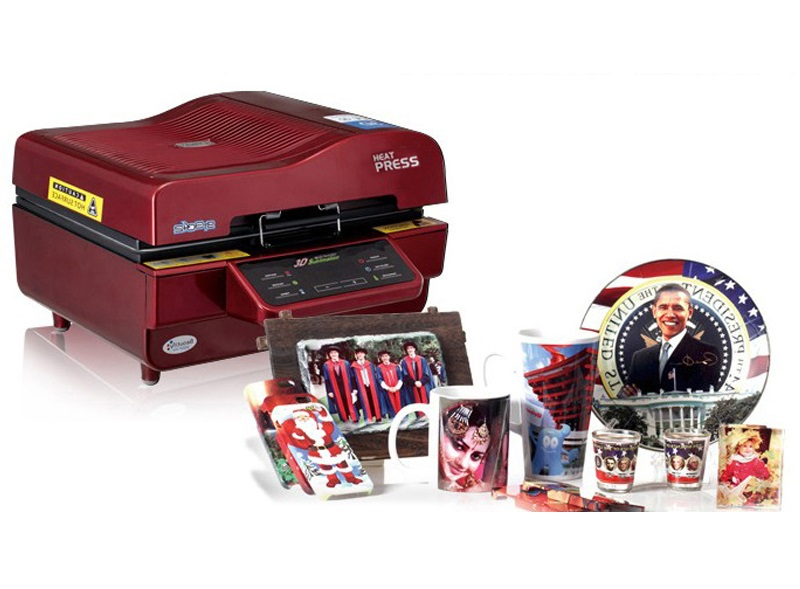

- Heating Press

- Hiipoo Sublimation Ink

- Epson ET-3760 Printer

- Sublimation transfer Paper

- Lint Roller

- Heat Resistant Tape

- Butcher Paper

- Fabric

Advantages :

Learn about the advantages of sublimation press:

- Vibrant colours appearance

- Long-lasting and durable.

- Versatile and can be used on multiple materials

- It Gives high-quality and detailed images.

- There is a lesser risk of peeling or faded colors

- Various colors on various patterns can be used

- The printing process from one garment to another is easier

- It provides a clean finish to the garment.

Try these fantastic fonts to design your garments.

Disadvantages:

Similarly, explore the disadvantages of sublimation press:

- Mostly effective on polymer-based material

- Requires expensive machinery system

- Precision and expertise are needed for optimal results.

- Can’t work on fabrics with less concentration of polyester material.

Screen Printing: A Concise Overview

Now, let’s delve into the details of the screen printing press:

Screen printing is the other method of printing. In this technique, a mesh screen transfers ink to a substrate, yielding a sharp and detailed image.  This method finds primary application in apparel, signage, and artwork.

This method finds primary application in apparel, signage, and artwork.

Process:

Embark on your screen printing journey today with these simple steps:

- Begin by placing the design onto a screen mesh with a light-sensitive emulsion.

- Expose the surface to UV rays, hardening the emulsion and creating an instant stencil pattern.

- Apply ink across the screen, pushing it through the stencil onto the material.

- Let the ink cool before applying heat for permanence.

- Finish with garment checks.

Applications:

Screen printing works best on:

Apparel: T-shirts, hoodies, and other clothing items.

Signage: Signs on Posters, banners, and promotional materials.

Artwork: Limited edition prints can be done with artistic creations on garments.

Ideal Substrates for Screen Printing:

These are the ideal substrates for achieving the best results through screen printing:

Textiles: Most presentable on Cotton, polyester, and blends.

Paper and Cardboard: Appropriate for posters, packaging, cards, and frames.

Metal and Plastic: Offers durability and versatility.

Material used for screen printing:

Stock your store with these raw materials used in screen printing:

- Transfer tape

- Heating press

- Vinyl based screens

- Cricut maker

- Tape

- Ink

- Fabrics

Advantages :

Know the advantages of screen printing:

- This method is much more economical and easy to apply.

- It gives a wide range of vibrant and sharp prints.

- Suitable on multiple materials with different ink types.

- Other categories of printing styles are accessible, like glitter, 3D, Or gradient.

- The high volume of fabrics can be printed.

Disadvantages:

Avoid screen printing if these disadvantages concern you:

- It can be a bit more time-consuming.

- Require high initial investment like labor and machines.

- It may not suit fine details compared to other methods.

- A limited amount of colors can be used, so only simpler designs can be made.

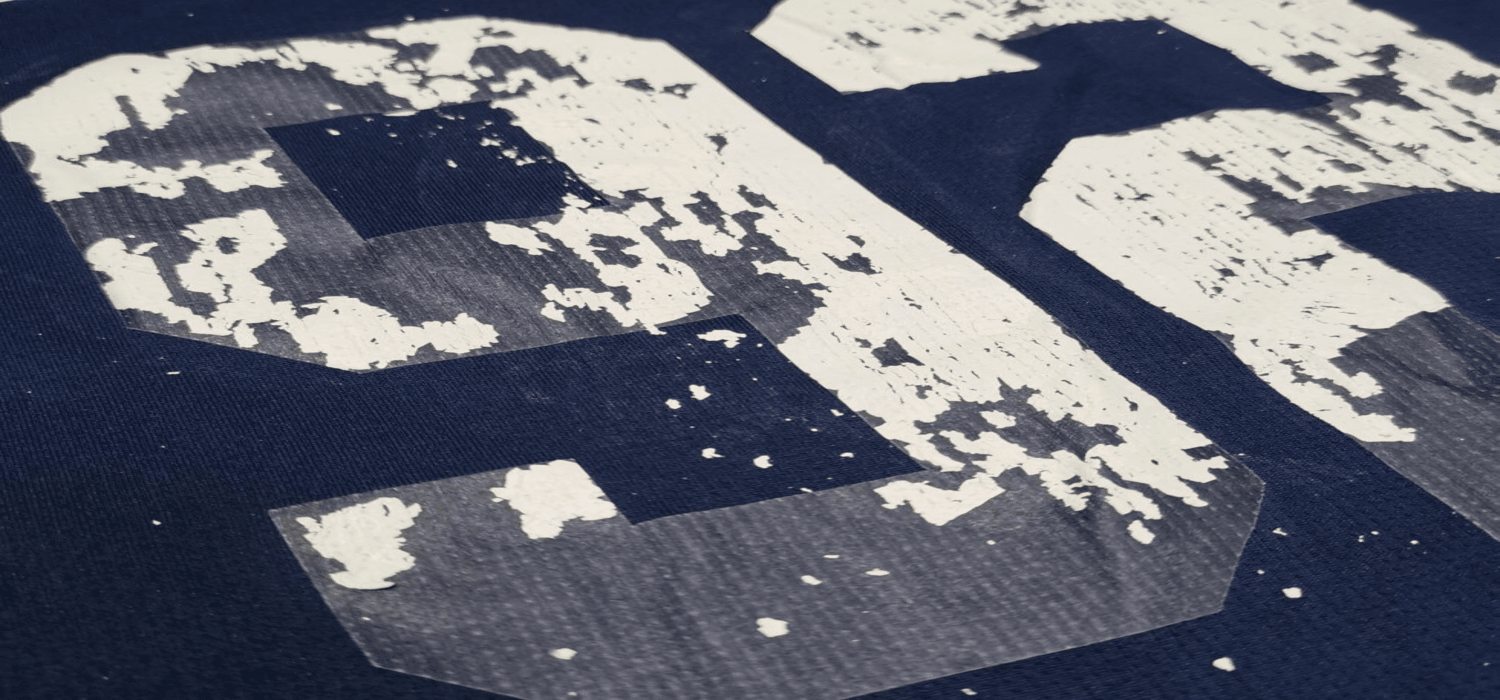

- Such printing designs may lead to cracks, peel, and fade finish after a more extended period.

Critical Differences

Let’s get into an elaborative description of sublimation vs screen printing:

Print Quality and Durability:

- Sublimation: It provides a good range of photo quality with vibrant colors. Inks get submerged into the material, which gives a long-lasting finish.

- Screen Printing: It provides a sharp, crisp design for text graphics. The color saturation is appropriate but does fade with time.

Know more about Innovative Graphic Design Business Ideas 2024

Print Complexity:

- Sublimation: The dye infusion process makes designs more intricate.

- Screen Printing: Suited for bold, simple designs, intricate details can be challenging, especially with multicolor prints.

Number of Colors :

- Sublimation: The significant difference between screen print and sublimation is that an unlimited amount of colors can be used in sublimation printing as it offers a digital interface. Avoid white colors as they may not be visible ideally.

- Screen Printing: Using separate screens for each color is time-consuming. They are making multicolor designs more complex and costly.

Special Effects:

- Sublimation: It can provide detailed and vibrant prints. Special effects like gradient designs are limited.

- Screen Printing: This printing technique allows various effects like metallic inks, glitter, and raised textures, expanding design possibilities.

Fabrics and Materials:

- Sublimation: This method is best suited for polyester fabrics and requires a polymer coating as the final finish.

- Screen Printing: This method is not limited to one fabric type but can be used on cotton, paper, cardboard, metal, and plastic, providing a broader material range.

Eco-Friendliness

Understanding the environmental degradation aspect of sublimation vs screen print is crucial before making up the mind. Read along:

Environmental Impact :

Identify how sublimation and screen printing affect the environment:

Sublimation:

- It is considered a more environmentally friendly measure as it uses low water and releases fewer chemicals.

- It requires more energy, and the potential emission of volatile organic compounds (VOCs) from sublimation inks poses concerns.

Screen Printing:

- This method consumes more water and has hazardous chemicals involved.

- The process itself has a lower energy footprint compared to Sublimation.

Waste Management:

Understand the waste management techniques of sublimation and screen printing:

Sublimation:

- Another significant distinction between sublimation printing vs screen printing is that the sublimation process produces fewer physical wastes as the inks become fully integrated into the material.

- However, disposal of used transfer paper and occasional cleaning waste requires attention.

Screen Printing:

- It generates more wastewater with chemical infusion done by inks.

- Ensuring proper disposal or recycling of these materials minimizes environmental impact.

Comparison at a Glance:

Here’s a nutshell covering all the possible aspects of sublimation vs screen printing:

Water Usage:

Water conservation is crucial. Learn more about the minimal water usage between both the presses:

- Sublimation: Requires low water usage.

- Screen Printing: Involves higher water consumption, particularly in cleaning screens.

Chemical Usage:

Analyze based on chemical consumption for both presses:

- Sublimation: Limited use of chemicals, but involves VOC emissions.

- Screen Printing: This is a more chemical-intensive process.

Energy Footprint:

Difference between the energy consumption:

- Sublimation: High energy use during heat transfer.

- Screen Printing: Lower overall energy footprint.

Waste Generation:

Identify which press produces the least waste:

- Sublimation: Minimal physical waste occurs, but disposal requires attention.

- Screen Printing: Generates more hazardous waste in screens and excess ink. It leads to water pollution.

Examples:

- Sublimation: Discarded transfer paper can be recycled. VOC-free sublimation inks contribute to a cleaner process.

- Screen Printing: Efforts in reclaiming and recycling screens and using eco-friendly inks can mitigate environmental impact.

Visit: 18 Best Home Design Software for Windows (2024)

Cost and Quantity: the difference between sublimation and screen printing

Delve into the cost and quantity differences between screen printing and sublimation methods. Moreover, understand how each handles expenses and production volumes in straightforward terms:

Sublimation:

- Most suited for on-demand and customized items.

- Provides a choice of various designs with lower investment.

- Potential for higher per-unit costs.

Screen Printing:

- Best suited for bulk production orders for the same designs

- Reduces per unit costs and initiates larger quantities.

- It requires a higher initial investment.

Choosing Your Approach:

Here are some crucial tips to note before making up your mind:

- Do analyze the demand and supply fluctuations of the economy.

- Sublimation printing is appropriate for smaller runs.

- Screen printing provides a more extensive interface for bulk orders.

- Align your choice with business goals, balancing upfront investment with long-term cost efficiencies.

Upfront Investment:

Understand the investment differences between the two presses:

Sublimation:

- Requires a modest upfront investment.

- Smaller in scale and easy to use.

- Requires less labor.

- Offers manageable initial costs, aligning with scalability.

Screen Printing:

- Investing a significant amount in set-up costs is necessary.

- Ideal for large businesses with bulk production capacity.

- Requires a large force of labor.

- Provides long-term advantages in per-unit expenses, making it favorable for enterprises committed to large-scale printing.

Selecting the Optimal Printing Method for Your Business

When choosing the type of press for your business, analyze the economic and budgetary context of sublimation vs screen printing:

Scenarios for Each Method:

Sublimation: Perfect set-up for business involving polyester-based products. Best suited for high-resolution images and intricate designs.

Screen Printing: Well-suited for large-scale projects, especially on fabrics like Cotton, and for bold, uncomplicated designs. Effective for high-volume production runs of promotional materials, apparel, and signage.

Tips for Choosing the Right Method:

Ensure to review these requirements before establishing the press:

- Consider Materials: Make sure the suitable material is used on sublimation and screen printing presses. Use polyester for sublimation and screen printing, offering versatility on various surfaces.

- Volume and Demand: Go with the ongoing demand in the market to avoid immediate loss—Analyze based on the budget used. Sublimation presses are suitable for smaller budgets, while screen printing is ideal for larger budgets and bulk production.

- Complexity of Design: Choose between the types of designs being used in printing. Sublimation’s digital process may be preferable for intricate designs, whereas screen printing efficiently suits more straightforward, bold designs.

- Environmental Impact: When evaluating Sublimation vs screen print transfers, one can discern meaningful differences that influence the quality and environmental impact.

See Also: 4 Websites to Generate Tumblr Usernames | Tumblr Username Generator

Faqs

Which is better, Sublimation vs screen printing?

The choice between Sublimation and screen printing hinges on material type, design complexity, and budget. Sublimation suits vibrant, all-over prints on polyester. At the same time, screen printing is excellent for intricate designs on diverse fabrics.

What are the disadvantages of sublimation printing?

Sublimation printing has limitations, requiring polyester fabrics for optimal results. It restricts material choices, making it unsuitable for natural fibers. Additionally, it may pose challenges when printing on dark-colored garments, as the process is most effective on light-colored or white surfaces.

What is better than screen printing?

Digital distribution methods include direct-to-garment (DTG) printing and outshine screen printing for intricate designs. Thinner ink layers in DTG ensure greater precision in the final print, making it ideal for detailed work on various fabrics. The result is high-quality, precise prints, surpassing the limitations of traditional screen printing.

Which printing is best for a T-shirt?

The optimal printing method for T-shirts relies on design, quantity, and material considerations. Direct-to-garment (DTG) printing excels for detailed, colorful designs on smaller batches, ensuring high-quality results. Meanwhile, screen printing proves cost-effective for larger quantities with simpler designs, offering durability and vibrant colors.

Conclusion:

Sublimation vs screen printing presented unique benefits for both techniques, tailored to distinct business requirements.

Moreover, sublimation shines with its ability to deliver vivid, intricate prints on polyester, while screen printing stands out for its cost-effective handling of large-scale production across diverse materials. It’s crucial to weigh factors such as material type, production volume, and design intricacy.

Additionally, or environmentally-conscious enterprises, a critical evaluation of the ecological impact is essential.

Ultimately, align your decision with your business objectives, whether emphasizing detailed designs, accommodating on-demand needs, or streamlining large-scale production.

Both methods offer advantages, providing tailored solutions for diverse business needs.

See Also: 14 Best Car Designing Software for Professionals [Updated]