Ethernet slip rings are like loops that help data move quickly between turning and fixed parts. They are essential for things like surveillance cameras on spinning bases because they keep communication unbroken.

This article covers a detailed description of the Ethernet slip Ring, including its functioning and features. Moreover, these slip Rings, to be very precise, are essential in rotational setups where continuous data sharing is needed. It gives a stable network connection, which is used in multiple industries. Ethernet slip rings come in different series, namely, ESE Series and ME Series.

Read the article to familiarize yourself with slip ring ethernet and its features. They are used across diverse industries through bots, windmills, and for sending equipment. They are most preferred in real-time communication—industries such as manufacturing, aerospace, and entertainment benefit from their supporting continuous connectivity in challenging environments. Why Does My Ethernet Keep Disconnecting? Check out here.

Table of Contents

What Are Ethernet Slip Rings?

Ethernet Slip Rings are, most importantly, a spinning system with connectors that make it easier for data to move between fixed and spinning parts, preventing damage.

Their core Functionalities include:

- Data Transmission: Ethernet slip rings transmit data signals from one interface to another, which is spinning. This activity avoids continuous communication.

- Multi-Channel Communication: It also employs multi-channel capabilities to support various data streams concurrently.

- Constant Ethernet Communication: Ethernet slip rings provide stable and rapid communication and spinning motion.

- Importance in Data Transmission: Ethernet slip rings play a motivating role in data transfer within dynamic systems.

- Essential for Real-Time Data Exchange: It is very much appreciated for enabling real-time data sharing. For example- they were sharing in automation and surveillance systems.

- Signal Stability: With Ethernet slip rings, it is possible to reduce signal interruption and data loss.

- Crucial for Broadcasting: When it comes to broadcasting, it enables the continuous playing of video feeds from turning cameras, ensuring smooth live broadcasts.

See Also: Fix: Ethernet Doesn’t Have A Valid IP Configuration Error

Application of Ethernet Slip Rings in Different Industries

While getting familiar with Ethernet Slip Rings, it’s suggested to know where they are used:

- Robotics: These Rings are used to improve the data-sharing steps in robotics. Such sharings are used for precise and organized motion in robotic arms and automated systems. In this way, the Ethernet slip ring contributes to various automated processes’ efficiency.

- Wind Energy (Wind Turbines): Ethernet Slip Rings are also used in releasing Wind Energy. They support the turning blade by enabling continuous monitoring and control for optimal performance. Their dependability is why wind energy systems have long and durable performance.

- Broadcasting Equipment: The sending equipment used a constant data transfer flow in turning cameras. Ethernet Slip Rings handle this need for exchanging data. The Rings initiate live broadcasts, ensuring continuous and high-quality video feeds.

- Manufacturing: Ethernet Slip Rings help exceed operational efficiency by providing consistent data flow in manufacturing. They help connect one interface to another and provide smooth machinery functioning in various manufacturing functions.

- Aerospace: Ethernet slip rings are used in the aerospace industry, where continuous and accurate data transfer is needed in turning components. Their cohesiveness makes them valuable in aerospace functions, further enhancing the overall performance of aerospace systems.

See Also: Does Dual-Band Router Switch Automatically? | How-To Guide

Key Features of Ethernet Slip Rings

Here are the prominent features that make Ethernet Slip Rings a must-have:

Data transfer speeds:

- In Ethernet Slip Rings, high-speed data transfer is a primary feature. They offer impressive rates of 100 Mbps and 1 Gbps.

- Such good speed assists in real-time and fast communication between turning and stationary components.

- Data transfer speed boosts productivity in various fields like machines, wind turbines, etc.

Power and Signal Combinations:

- Slip Rings are versatile when concurrently managing power and signals.

- They can handle multiple power or signal combinations together. It makes them very adaptable to the complex needs of rotating systems.

Contact Material and Electrical Noise:

- These Slip Rings produce minimal noise in high-quality contact materials used in these slip rings. It reduces disturbance.

- This feature is particularly significant in purposes like surveillance systems and sending equipment, where accuracy and clarity in data transfer are critical for effective performance.

Compatibility with Data Bus Protocols:

- These rings are compatible with data bus protocols like Profibus, DeviceNet, and EtherCAT.

- Such compatibility helps them to integrate into different systems while maintaining versatility.

- This compatibility factor makes them a preferred choice for functions demanding adherence to specific data bus protocols, ensuring a smooth integration process across diverse environments.

Additional Features:

- It often incorporates advanced materials like gold-plated contacts, enhancing conductivity and durability.

- They also have an IP rating protecting them from dust and water and making them durable in challenging environments.

- By reducing wear and tear, these slip rings play a role in extending the lifespan of the equipment.

Types and Specifications of Ethernet Slip Rings

The specifications of these Slip Rings are as follows:

Different Series:

ESE Series: Renowned for its precision and compact design, it works for limited space functions. They provide reliable data transfer in a rotating manner. Makers mainly use this series in machines and small-scale automated setups.

ME Series: The ME Series stands out for its robust construction designed for demanding industrial environments.

Employed in robust functions, it boasts remarkable durability. Wind turbines, manufacturing machinery, and other high-stress industrial settings primarily use it.

Technical Specifications:

Current Rating: These Ethernet slip rings provide a versatile range of current ratings. They cover functions from low-power scenarios to those requiring higher currents. This way, they act as a compatible ring that works with various devices and setups. The current rate ranges from Milliamps to several amperes.

Voltage Rating: Ethernet Slip Rings are a flexible voltage rating system. They can adjust to different voltages and are appropriate to work in diverse power systems and functions.

Maximum Data Speed: These slip Rings offer maximum data speed to embrace real-time communication and high-speed data sharing.

Temperature Range: They are compatible with any temperature, including extreme ones. They operate in both hot and cold environmental conditions with optimal performance.

Setups and Models Available:

Ethernet slip rings present diverse setups, providing tailored solutions for specific needs.

Capsule Models for Compact Spaces: The capsule-looking model is perfect for compact spaces. It works the same as others and does not compromise on performance.

Medical devices primarily use them where space constraints require an efficient yet reliable solution.

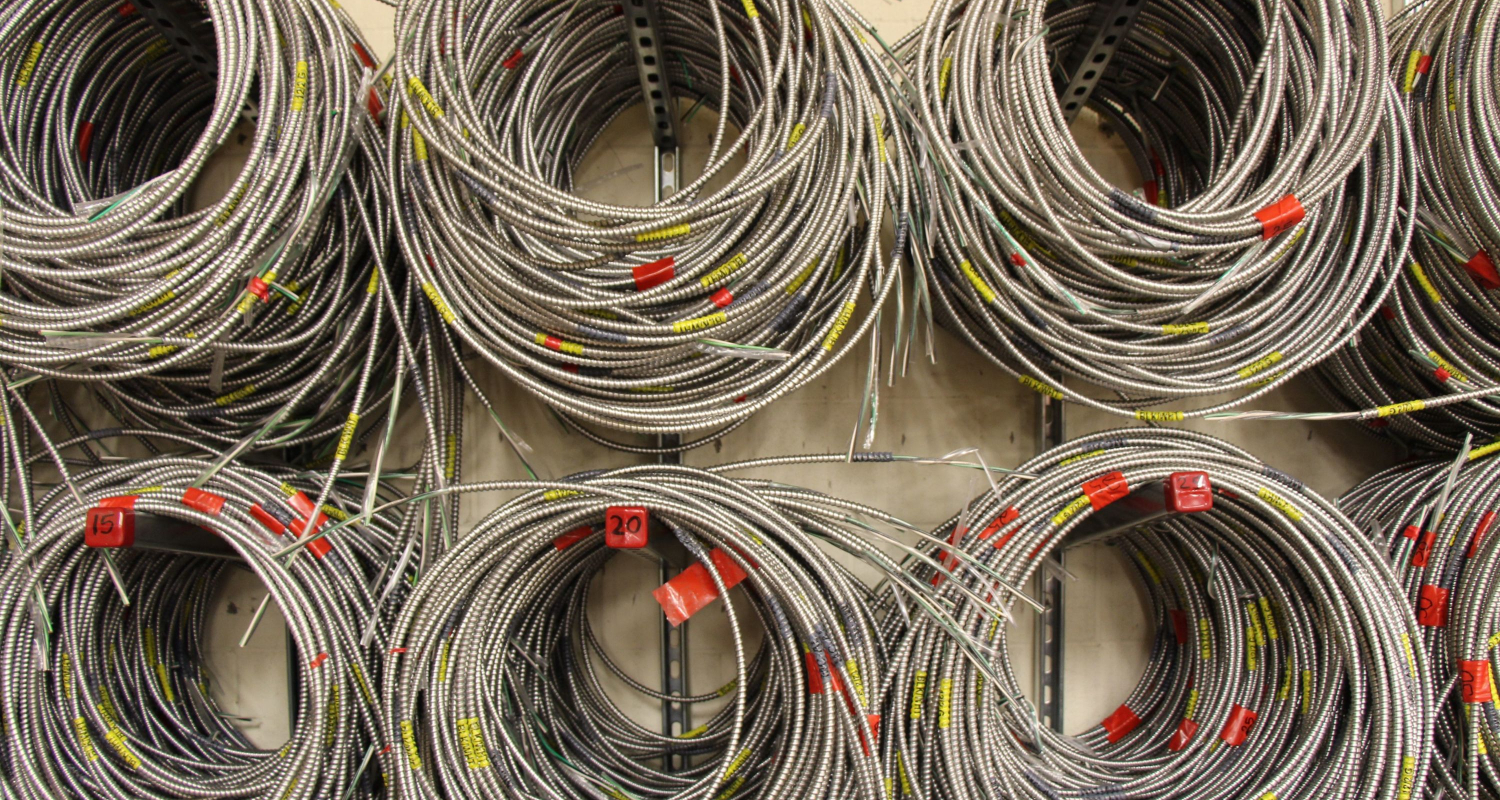

Through-Bore Models for Versatility: Ring models have a central opening for cable passages. These kinds of Rings add versatility to cable management.

In machines, companies primarily use them because they easily accommodate complex cable setups.

Pancake Models for Low Profile Needs: The pancake model of Ethernet Slip Rings is the lower profile Rings that cater to higher constraints. Surveillance cameras use them, providing a secret and minimal look to avoid drawing attention.

Customizable setups for Unique Functions: Some Ethernet slip rings present customizable setups, allowing users to tailor the design to specific application needs. Their versatility renders them suitable for a wide range of industrial markets.

Installation and Maintenance of Ethernet Slip Rings:

Now it’s time to know the installation process of Ethernet Slip Rings:

- Preparation: The first step is preparing the tools and equipment required to install them. These tools can be mechanical tools like screwdrivers, bolts, etc.

- Alignment: In the next step, Ethernet Slip Rings must be aligned to avoid operational issues.

- Connection: Ethernet Slip Rings should be rechecked through cables to observe the guarantee of continuous data transfer.

- Testing: Conduct comprehensive testing during the installation phase to confirm the proper functionality of the Ethernet slip rings.

- Secure Fixation: Secure the slip rings in the desired position to prevent inadvertent dislodging.

- Final Check: Remember to have a last check of the working of the Rings. Verify all the connections before concluding the installation process.

Precautions during Installation:

Remember these precautionary tips while installing the Ethernet Slip Rings:

Avoid Over-Tightening: Excessive tightening of components might lead to Breakage or cause damage to the Rings.

Environmental Considerations: While the rings are weather-compatible, shades are still suggested to prevent dust, moisture, and extreme temperatures from affecting them, ensuring optimal performance.

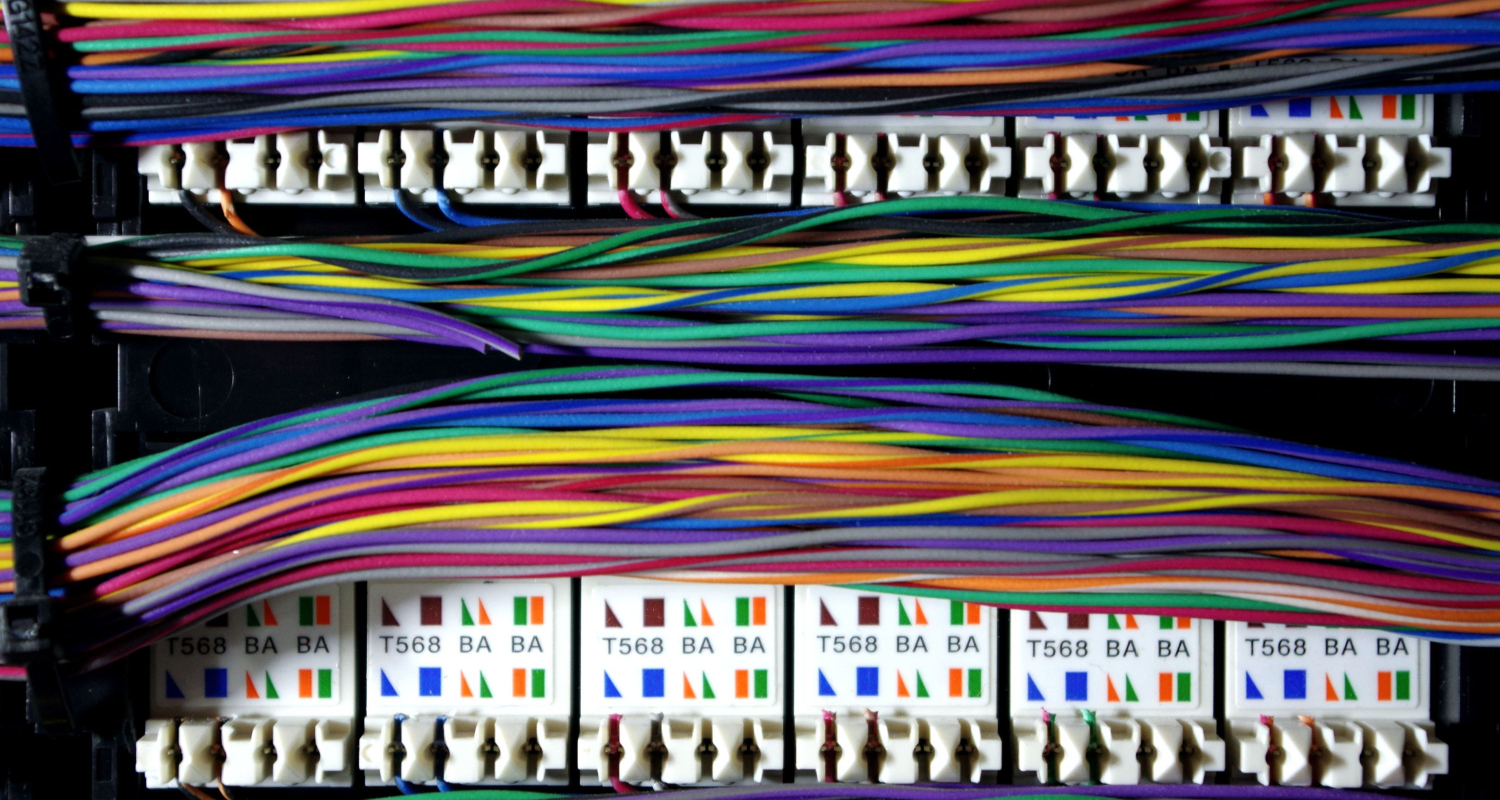

Cable Routing: Use clean roles of cable routing to prevent tangling or undue strain on the Ethernet slip rings.

Anti-Seize Lubrication: Applying anti-seize lubricating to threaded components is a must. It protects the Rings from corrosion and provides future maintenance.

Static Discharge: Implement measures to ground personnel to prevent static discharge during installation.

Expert Consultation: To ensure accuracy, you can also seek expert guidance, especially in complex installations.

Routine Maintenance:

- Frequently check the Ethernet Slip Rings to notice any wear or tear.

- It’s suggested to clean the Rings regularly to maintain optimal conductivity.

- Keep an eye on its functioning and notice any unusual sounds.

Troubleshooting Ethernet Slip Rings:

Instructions to repair the Ethernet Slip Rings:

Check for Loose Connections: Inspect all connections of Slip Rings for secure fastening.

Cable Inspection: Do examine cables for any signs of damage or tear repair if found.

Alignment Verification: Then look for proper alignment or fixation of wires as it will give smooth operation.

Testing Continuity: Conduct continuity tests to verify good electrical connections.

Review Operational Logs: You can also analyze operational logs for irregularities or error patterns.

Ensuring Longevity and Optimal Performance:

Preserving Ethernet slip rings is crucial for cost savings and significant benefits.

- A proactive maintenance routine is perfect to prevent potential issues in the very beginning before they grow further. Such a schedule includes regular inspections, too.

- Regular lubrication over the rings protects them from friction, Breakage, or roughness. It gives a smooth functioning of the rings.

- Further, monitoring the rings in environmental conditions is crucial as they prevent rings from corroding in humidity. Ensure they remain within specified operating parameters, preventing potential damage.

- You can also ask for help or appoint an assistant to check the Ethernet Slip Rings regularly.

- Recording, tracking, and analyzing performance trends over time are necessary, along with preventive methods.

- Address identified issues promptly to prevent extensive damage, ensuring optimal Ethernet slip ring performance.

Use in Factory Automation: Case Study

In the thrilling world of factory automation, Ethernet slip rings emerged as game-changers.

Picture this: Integrating robotic arms with slipt, meaning as smooth as butter, these incredible slip rings brought a new level of precision to assembly processes.

But it doesn’t stop there! In conveyor systems, they ensured the balletic synchronization of material motion, i.e., the talk about a symphony of efficiency is provided.

When it comes to automated inspection systems, these slip rings didn’t just contribute; they turbocharged data sharing, ramping up the speed and accuracy of quality control. It’s as if they whispered the sweet language of efficiency to every machine, crafting a marvel in manufacturing.

See Also: Fix Playback Failed Check Log for More Information Error

Application in Machine Tools

Here are the uses of Ethernet Slip Rings in machine tools. Have a look:

- CNC Machining Centers: The Ethernet Slip Rings help form smooth communication between computer numerical control (CNC) systems and machine tools; they provide precision and efficiency.

- Data Feedback Systems: Additionally, it is used for interpreting data from sensors and encoders in machine tools, contributing to real-time monitoring and control.

- Automated Tool Changes: The rings facilitate communication for mechanical tool change systems, thereby enhancing the productivity of machines.

- Robotic Integration: The Rings promotes communication between mechanical systems and machine tools, optimizing coordination for complex manufacturing processes.

- Process Monitoring: They are used for real-time data sharing in process monitoring systems. This feature increases their quality control and performance optimization.

- Tool Positioning Systems: The Rings are also used for passing data between tool positioning systems. It gives accuracy in machining operations.

- Adaptive Machining: The Rings enable connectivity in adaptive machining systems, allowing machines to adjust parameters based on real-time feedback for improved results.

- Networked Manufacturing Cells: Support networking between various machine tools in manufacturing cells; in other Industrial Functions, Ethernet Slip Rings are used in multiple areas. Let’s know more:

Other Important Tools

- Medical Devices: In the medical field, robotic surgery and diagnostics require reliable data transfer through ring ethernet.

- Material Handling: Automated conveyor systems benefit from their use as Ethernet slip rings enable continuous communication systems for efficient material handling.

- Renewable Energy: Ethernet Slip Rings find extensive use in solar panels for tracking and transmitting data in solar farms.

- Automotive Manufacturing: They can further wind their way into robotic arms and assembly lines for communication in automotive production.

- Industrial Robotics: In the new industrial revolution, using Ethernet slip rings in diverse mechanical functions, including manufacturing, welding, and assembly processes, is paramount. These versatile components are why smooth communication and coordination can happen, enhancing the efficiency and performance of industrial machines.

- Oil and Gas: Functions of Ethernet slip rings encompass their use in drilling rigs and remote monitoring systems. Consequently, they facilitate efficient data sharing, enhancing coordination and performance in these applications.

- Mining: Ethernet slip rings facilitate communication between sensors and control systems. This connectivity enhances data transmission and coordination, improving efficiency and safety in mining operations.

- Marine: Remotely operated vehicles (ROVs) and offshore drilling platforms also utilize them for data transfer in challenging marine environments.

Choosing the Right Ethernet Slip Ring for Your Needs:

Current Capacity: Always check the Ring’s current carrying capacity to ensure whether you can deliver that current range to it or not.

Mechanical Compatibility: The Ethernet Slip Rings should also be chosen based on the size and form. These factors help fit the Rings easily in the system without hindering mechanical operations.

Environmental Conditions: It’s also intelligent to check the environment for temperature, humidity, and contaminant exposure. Consequently, choose a slip ring with suitable protection, ensuring its optimal performance and longevity in specific environmental conditions.

Maintenance needs: Opt for slip rings with low maintenance needs; this choice helps reduce downtime and minimize costs, contributing to an efficient and cost-effective operational setup.

Precision and Signal Quality: Prioritize slip rings that maintain signal integrity and, additionally, offer precision. This feature is crucial for functions demanding accurate data transmission, ensuring reliability in critical applications.

Cost-Effectiveness: A slip ring should be within an appropriate cost frame. Furthermore, its performance should complement the amount spent on it, ensuring a balance between quality and expenditure. Ultimately, it should align with your budgetary constraints.

Durability and Longevity: Go for a slip ring with robust construction materials; this ensures durability and a longer operational lifespan, providing a reliable solution for your long-term needs.

Customization Possibilities: Choose slip rings that offer customization options. This way, you can tailor them to unique application needs, ensuring a perfect fit for your requirements.

Customization options These Slip Rings:

Contact setups: Ensure the accurate number and types of contacts align seamlessly with your application’s specific data transfer needs. Consequently, this precision guarantees an efficient and tailored solution for your connectivity requirements.

Cable Length and Type: Consider the cable length and style of the setup; accordingly, ensure optimal performance and dependability in environmental conditions.

IP Rating: While customizing, you must specify the Ingress Protection (IP) rating to safeguard the slip ring from dust, moisture, or harsh conditions, aligning with your environmental needs for better durability.

Operating Speeds: Choose the correct operating speeds similar to the required data transfer rates and prevent communication bottlenecks in your system.

Material Selection: In selecting materials for Ethernet Slip Rings, the factors to be considered above all are conductivity, durability, and corrosion resistance to ensure longevity and dependability.

Integration with Sensors or Encoders: One should also integrate the Rings with sensors or encoders as it provides smooth communications, especially in functions requiring additional data feedback.

Temperature Range: Specify the temperature range for optimal performance in your operating environment. Consequently, prevention of issues related to overheating or freezing.

Mounting Options: Tailor mounting options to integrate the slip ring into your system smoothly. Additionally, this factor curbs space-related problems and manages the ease of installation.

See Also: How To Connect Two Computers Using LAN Cable For Data Transfer

Consulting with Makers and Tips:

It’s time to discuss the Ethernet slip rings with the dealer. This interaction is, above all, as it provides valuable insights into its features and specifications.

Clear Communication: Discuss the features, needs, environmental conditions, and safety before buying it.

Sample Testing: The buyer should also ask the manufacturer to run a sample test in front of someone.

Technical Support: The Ethernet rings, to be very precise, ensure that there is robust support for the rings, along with tailored security. These rings also provide a reliable network structure, enhancing stability and data protection.

Customization Clarification: If you are customizing the rings, it’s crucial to understand their features and lead times. Consequently, in such analysis, a better ring option could develop.

Warranty and After-Sales Service: While conversing with the dealer, providing locals with the benefits is suggested,

Like after-sales service for ongoing support.

Stay Informed: Stay updated on technological advancements and industry standards to make informed decisions when choosing Ethernet slip rings.

FAQs

Can one use Ethernet slip rings outdoors?

Many Ethernet slip rings incorporate protective features, such as sealing and materials resistant to environmental conditions. So, these rings make them suitable for outdoor functions.

Do slip rings require regular maintenance?

Yes, routine maintenance is crucial to ensure optimal performance. Moreover, periodic cleaning and checking help in preventing wear and ensure longevity.

Can slip rings handle high data transfer speeds?

The design of Ethernet slip rings to handle high data transfer speeds, which, as a result, makes them suitable for real-time communication and data sharing functions.

Are slip rings compatible with various protocols?

Many Ethernet slip rings support compatibility with data bus protocols like Profibus, DeviceNet, and EtherCAT. They overall ensure versatility in different functions.

Conclusion

In a nutshell, Ethernet slip rings are like super connectors that help things spin while keeping them connected. They’re crucial for sending data smoothly between things that move and things that stay still. According to the Moog definition, ring Ethernet offers a reliable solution for transferring the Ethernet protocol through a turning interface, ensuring dependable product performance.

This article covers how Ethernet slip rings work, where they’re used, and what to think about when choosing the right one. Think of them as heroes in a factory, helping machines talk to each other. They’re great in assembly lines, making devices work together really precisely. On conveyor belts, they help materials move smoothly. And in inspection systems, they’re like rock stars, making quality checks faster.

What does the future hold for these connectors in our ever-growing world of machines and automation? Comment down below!

See Also: How To Use Chromecast Without Wifi In 10 Easy Steps